|

Discussion forum for the various methods and structures used for getting an early start on your growing season, extending it for several weeks or even year 'round.

|

|

|

|

Thread Tools | Display Modes |

|

|

#16 |

|

Tomatovillian™

Join Date: Jul 2015

Location: Lincoln, NE

Posts: 192

|

I decided to go with Johnnyseed's Gothic Arch Bender. I drafted a "wall section" plan and will be applying for building permit tomorrow. According to city building and zoning folks, I'm cleared for a greenhouse on my lot as long as it for personal, not commercial use. I'm going to be ★★★★ed if there is a snafu in getting the permit, I just placed a Johnnyseeds order!

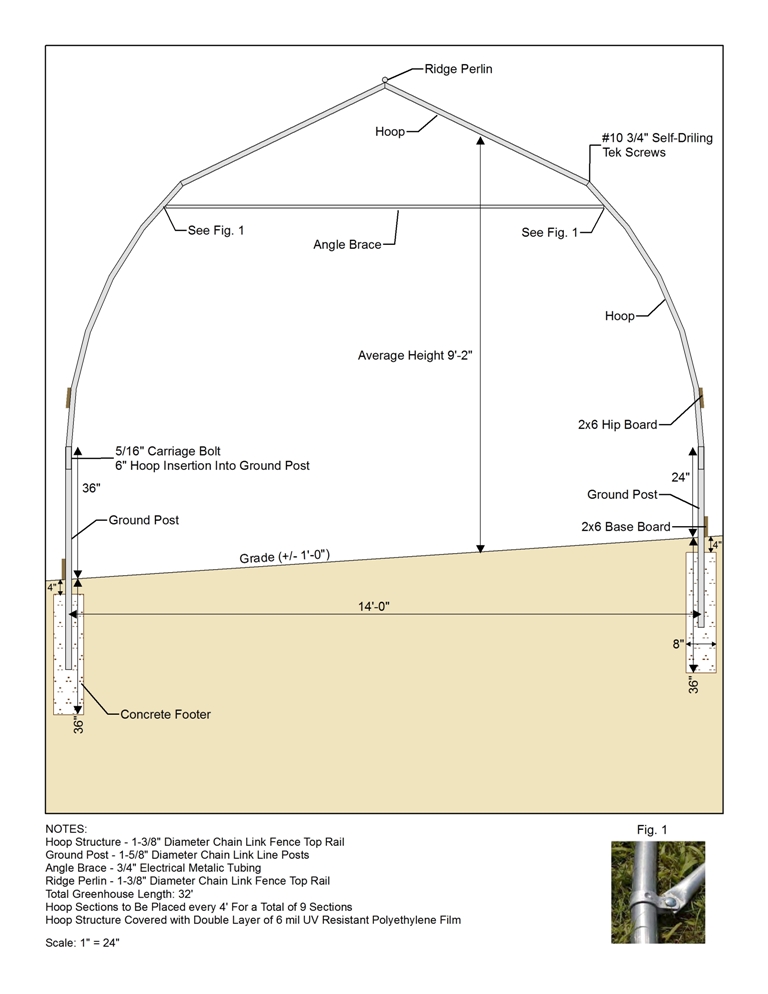

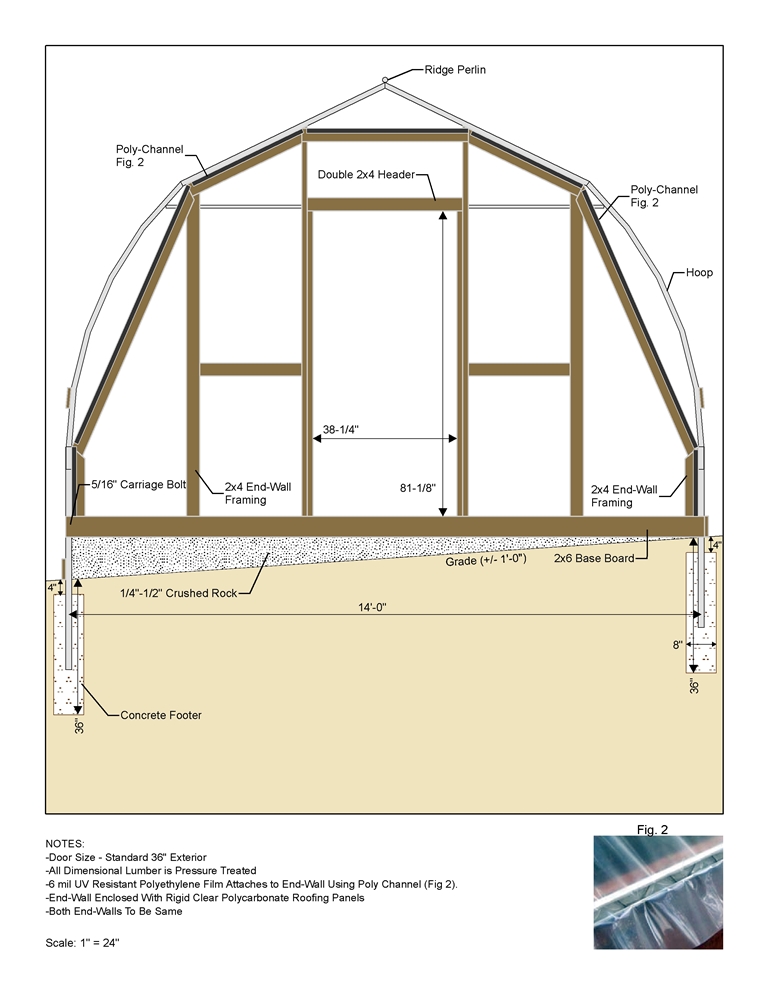

32' Long X 14' Wide X ~9.5' Tall at center double layer clear 6 mil poly film. Johnnyseeds spacer blocks between layers Roll-up sides End walls will be identical; treated 2x4, covered with clear rigid roofing panel (home depot) I'll get used storm doors on craigslist

Last edited by pecker88; February 12, 2016 at 08:27 PM. |

|

|

|

|

|

#17 |

|

Tomatovillian™

Join Date: Jun 2012

Location: Illinois, zone 6

Posts: 8,407

|

Neat. That's exciting.

For what it's worth, you really only need concrete on the corner posts, unless your soil is very sandy with no clay. 2x4s should be fine for the hip boards, instead of 2x6s. And for the plastic below the hip board, you want a single layer, because you can't inflate the part that rolls up, at least as far as I know. I doubled the plastic in that section and mine turned cloudy from rubbing together. A single layer would have been better. Your two end purlins take the brunt of the wind. When a greenhouse collapses from wind, the end purlins twist, and then it all falls in. If you want to strengthen your structure, extra bracing for the each end rafter is the first place to start. |

|

|

|

|

|

#18 | |

|

Tomatovillian™

Join Date: Jul 2015

Location: Lincoln, NE

Posts: 192

|

Quote:

|

|

|

|

|

|

|

#19 |

|

Tomatovillian™

Join Date: Aug 2015

Location: Zone 6a Denver North Metro

Posts: 1,910

|

That's a beauty!

|

|

|

|

|

|

#20 |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

Another thing I would like to add.

If you are going to sink pipe up into concrete footings make sure the concrete is above grade. Also it will last almost forever if you wrap it in underground pipe wrap. I would much rather use anchor plates on the bottom of the metal and bolt it to the concrete. Do this by putting your J bolts in the concrete before it sets up. Make a plywood pattern just exactly like the pattern of the support plate put your bolts and nuts one it and set it in the concrete so it doesn't move around or sink. Worth |

|

|

|

|

|

#21 | |

|

Tomatovillian™

Join Date: Jul 2015

Location: Lincoln, NE

Posts: 192

|

Quote:

|

|

|

|

|

|

|

#22 |

|

Tomatovillian™

Join Date: Mar 2014

Location: Mid-Atlantic right on the line of Zone 7a and 7b

Posts: 1,369

|

What do you figure you'll have in it, not counting your raised beds as they are already built? If you don't mind me asking?

|

|

|

|

|

|

#23 | |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

Quote:

I was thinking more on the lines of a catastrophic event such as the collapse of the structure. This way you could start over without having a bunch of pipe or what ever stuck in concrete you couldn't do anything with. To prevent frost heave pour the footings down below the frost line. Worth |

|

|

|

|

|

|

#24 |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

You should try to build something on permafrost and see the mistakes people make.

The building heats up the permafrost and the whole thing sinks in the ground.  Worth |

|

|

|

|

|

#25 | |

|

Tomatovillian™

Join Date: Jul 2015

Location: Lincoln, NE

Posts: 192

|

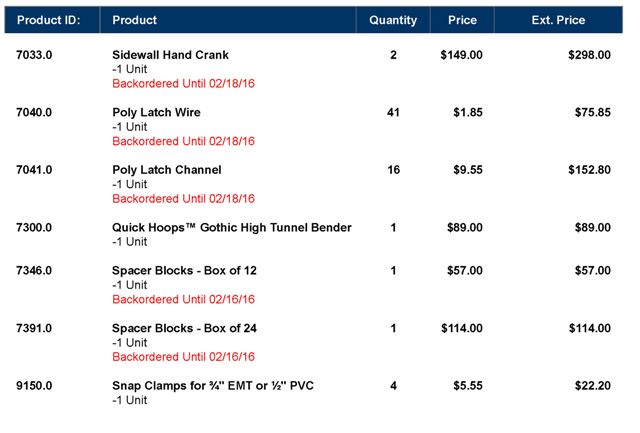

Quote:

I'm doubling my current raised bed area so I have roughly 1/2 the soil I need. The city gives away free compost in the spring, I'll go get a few pickup loads. I just found out about this program yesterday, seems too good to be true: see here The above order from johnnyseeds was $812.85 including shipping. I'm waiting on the rest of the material until spring, and so my wife doesn't loose her cool. Items remaining: treated lumber for hip/base boards and end walls - $200 clear poly roofing panels for end walls - $80 hor/vert enclosure strips for corrugated roofing panels - $20 hardware - $50 storm doors - $50 double 6 mil poly covering, 40x75 ft - $380 10ft chainlink top rail - $350 8ft chainlink line posts - $150 chainlink fasteners misc. - $40 quality landscape fabric for under/around line posts - $125 parachute cord for lacing roll-up sides - $40 sub total: $1485 grand total: $2298 seems reasonable for a cathedral shape 32x14 structure with double poly, no blower. Last edited by pecker88; February 11, 2016 at 05:44 PM. Reason: forgot item |

|

|

|

|

|

|

#26 | |

|

Tomatovillian™

Join Date: Jul 2015

Location: Lincoln, NE

Posts: 192

|

Quote:

But several building forums mentioned that above-grade footers with anchors like you explained are for downward point loads, (houses, decks) and not so much for fences. The physics in my head seemed to justify their claim, but I'm by no means an expert. |

|

|

|

|

|

|

#27 | |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

Quote:

One the bottom of the fence is at ground level. Two you dont see the ugly footers sticking up. Three the soil wont wash away and leave the footing sticking above ground. We dont have frost heave here where I live in Texas but we do have something else and that is in many places clay soil. No one builds a house on clay soil here that is worth a hoot. They may pour footers and the slab but they dont drop pilings below the line in the clay where it doesn't get dry and wet. Now everyone has a house that moves around. One way to stop this is to put in rain gutters and channel the water away that is what I did. Another thing to do is to excavate out around the area of the house and put a layer of stabilized sand down on top of the clay before you pour the slab. That slab needs to be on a vapor barrier. Worth |

|

|

|

|

|

|

#28 |

|

Tomatovillian™

Join Date: Jun 2012

Location: Illinois, zone 6

Posts: 8,407

|

Your roll-up sides will need something to roll around if you want them to roll neatly, typically top-rail. For my high tunnel, I just pull up the sides and clamp or bungie them to hold them up. It doesn't look as neat, but it works.

This stuff is great for attaching plastic to lumber for the end walls and doors: http://growerssolution.com/PROD/batten-tape/BTFS |

|

|

|

|

|

#29 | |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

Quote:

Were I put the soil back to where it belonged next to the house is where I want to put a shed green house made out of wood with a wood floor like a deck. Worth |

|

|

|

|

|

|

#30 | |

|

Tomatovillian™

Join Date: Jul 2015

Location: Lincoln, NE

Posts: 192

|

Quote:

10ft sections of 3/4 EMT + fittings - $60 I'm following JS's guide, almost exactly; they said to construct roll-ups with 3/4" EMT. I ordered a bunch of poly-channel & wire from JS's; that's how I'll attach poly to side walls. For end-walls I'm going to build a 2x4 frame that roughly follows the arch, then attach the poly-channel to the 2x4's. The poly film gets ran over the end of the end-wall arch, and straight down to the poly-channel. Just below the poly-channel on the 2x4 I'll fasten the rigid clear roofing panels. Seems like a good way to "union" poly film and rigid poly roofing panels. Example pic: note the poly-channel running along the 2x4 under the arch. Same idea.

|

|

|

|

|

|

| Thread Tools | |

| Display Modes | |

|

|