|

|

#151 | |

|

Tomatovillian™

Join Date: Jul 2008

Location: 6a - NE Tennessee

Posts: 4,538

|

Quote:

If I don't care to use the skins and seeds, I have lots of little buddies like Gold Finches that love to eat the seeds. Many of the birds won't touch the seeds if they've been cooked. Even that darned Chipmunk wants what he steals to be raw. We both cut tomatoes up. But then our methods go separate routes. By the time you bring yours off the stove, I'm sitting in my chair checking out Tomatoville, watching a golf tournament, or just resting from a hard day in the garden while the mix cooks down. By the time you get to that electrical appliance, my kitchen is cleaned up, and I'm done and off to another project or just taking a nap. My "hands-on" time takes about two hours for a dozen quarts of thick juice. So, who really made extra work without purpose? That old saying, "There's a lot of ways to skin a cat" applies here. I can see that your process gets you the results you want. And, my processes get the results I want. And, everything I do has purpose. Else, I don't do it. -

__________________

Ted ________________________ Owner & Sole Operator Of The Muddy Bucket Farm and Tomato Ranch |

|

|

|

|

|

|

#152 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

http://www.durgan.org/2015/July%2020...%20Juice/HTML/ 28 July 2015 Cucumber Juice

Excess cucumbers, plus some large tomatoes, some grapes tomatoes ,green pepper was made into 11 liters of juice. Total weight was about 16 pounds.The produce was pressure canned at 15 PSI for 15 minutes for storage. Pictures depict the process.

|

|

|

|

|

|

#153 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

http://www.durgan.org/2015/July%2020...%20Juice/HTML/ 31 July 2015 Blueberry Juice

Twenty three pounds of blueberries were picked from a local farm.The berries were washed, placed in a pot and covered with water.Cooked until soft about 15 minutes then beat into a slurry with a hand blender.The juice was then strained through a typical mesh screen to remove any picking debris. There is almost no cellulose fiber in blueberries.The strained juice was placed n liter jars and pressure canned in two batches of 7 for storage. Cost was $2.25 per pound and translates to about 1.6 pounds of berries per liter of juice.Each jar of juice costs about $3.25.

|

|

|

|

|

|

#154 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

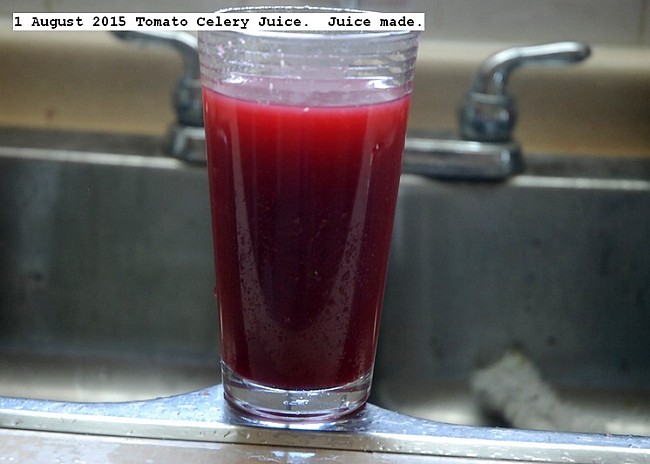

http://www.durgan.org/2015/August%20...%20Juice/HTML/ 1 August 2015 Tomato Celery Beet Juice.

Ten pounds of tomatoes, 5 pounds off celery, and two pounds of beets were made into 14 liter jars of juice.The beets were added to enhance the red color of the juice.Process was to cut into smaller pieces, cover with water in the cooking pot. Cook until soft and beat into a slurry with the hand blender. Strain through a food mill or screen in my case a Victorio. The residue output of the Victorio as put through a Champion Juicer to extract most of the nutrients.Only the most gross cellulose material was discarded. The juice was put into liter jars and pressure canned in two batches of seven at 15 PSI for 15 minutes for long term storage at room temperate.

|

|

|

|

|

|

#155 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

http://www.durgan.org/2015/August%20...%20Juice/HTML/ 2 August 2015 Cucumber Collards Juice

Fifteen liters of cucumber collards juice was made, since both are readily available from the garden. Some garlic, onions, basil, and tomatoes were incorporated. The onions and garlic was blended with water prior to adding to the cooking pot. The cooked material was blended into a slurry, strained and placed in liter jars for pressure canning at 15 PSI for 15 minutes for long germ storage.Pictures depict the process. http://www.durgan.org/2015/August%202015

|

|

|

|

|

|

#156 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

http://www.durgan.org/URL/?DGVNO 24 August 2013 Peach Juice

Redhaven Peaches were ripe so were processed into 16 litres of juice. A total of 25 pounds were picked.The pits were hand removed and five litres of water was added to the cooking pot. Each litre of juice contains about 1.5 pounds of peaches. The peaches were cooked until soft and blended into a slurry.The slurry was put through a food mill strainer. The residue from the food mill was used as a dessert.The peaches were small but excellent quality.The juice was pressure canned at 15 PSI for 15 minutes. My peach tree was frost damaged on 23 May 2015. The buds were frozen, hence no peaches this year from my garden. Today 20 pounds of peaches were purchased and will be made into juice as depicted above when they are ripe in about four days. Cost was about $1.50 per pound. The peaches were from the Niagara Falls area. |

|

|

|

|

|

#157 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

http://www.durgan.org/2015/August%20...HTML/index.htm 21 August 2015 Sweet Potato Juice

Ten pounds of sweet potatoes were purchased from a local farmer and processed into 14 liters of juice.The potatoes were washed, trimmed and cut into small chunks for cooking. Ten liters of water was added and the potatoes were cooked until soft,about 20 minutes, and blended into a slurry. Seven liters of the slutty was strained through a food mill and the other seven was canned without straining. There is almost no residue from the process.The liter jars were pressure canned at 15 PSI for 15 minutes for storage.The juice is sweet and most appetizing.

|

|

|

|

|

|

#158 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

http://durgan.org/2015/August%202015...HTML/index.htm 22 August 2015 Peach Juice

Twelve pounds of locally purchased peaches were processed into 12 liters of pressure canned juice.Cost about $1.50 per pound. The peaches were washed, pits removed by hand squashing, 6 liters of water added to cooking pot. Cooked until soft about 20 minutes, blended into a slurry, processed through Victorio strainer. The Victorio residue was put through a Champion juicer. The 12 liters of juice was pressure canned in two batches, since pressure cooker holds seven jars, at 15 PSI for 15 minutes for long term storage at room temperature.

|

|

|

|

|

|

#159 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

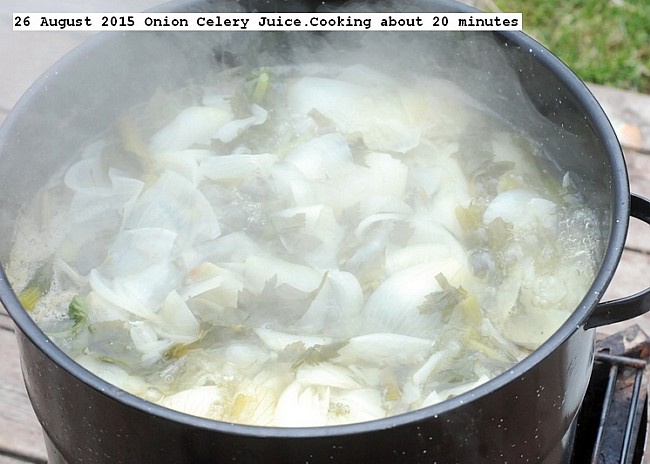

http://www.durgan.org/2015/August%202015/26%20August%202015%20Onion%20Celery%20Juice/HTML/ 26 August 2015 Onion Celery Juice

Thirty pounds of onions and ten pounds of celery was made into 14 liters of juice.The perfect onions were washed and quartered and added to the celery in the cooking pot. Ten liters of water was added to the pot.Material was cooked until soft about 20 minutes and blended into a homogeneous slurry.The slurry was strained through a Victorio food mill. Th residue of the food mill was put through a Champion Juicer to extract all nutrients.The juice was then placed on liter jars and pressure canned at 15 PSI for 15 minutes.

|

|

|

|

|

|

#160 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

Pressure Canning (My Method)

Posted on August 26, 2015 by Durgan My Method of Pressure canning. Only plant material is pressure canned.The produce to be canned for long term storage at room temperature is: Washed,cut into smaller pieces, added to a large cooking pot, covered with water to make a drinkable texture. Cooked until soft, about 20 minutes. When soft, blended into a homogeneous slurry with a hand blender.The slurry is then strained through a food mill or screen usually about 2mm mesh.The residue from the food mill or screen is usually put through a Champion Juicer to recover the maximum nutrients. This product usually a small amount makes a fine soup base or can be mixed with the food mill juice. The juice obtained is them placed in liter jars,which are placed in the pressure canner. The pressure canner, a Presto, handles 7 one liter jars per batch.The canner is set for about 50 minutes, without the rocking weight in place until steam pours vigoursly out the vent. This usually takes about 30 minutes or more.Then the weight is installed and when it starts to rock indicating 15 PSI, the 15 minute timing commences.At the end of the timing interval, heat is turned off and the pressure cooker is allowed to cool naturally.Lids are checked for seal and any not sealed are re-pressure canned with a new lid, or the jar of produce is used within a few days.I reuse the lids if not damaged and the failure rate is similar to using new lids each time, very minimal. Water in the pressure canner is 3 liters. The gasket surface is lightly oiled by running the finger over the surface with kitchen vegetable oil. This extends the life of the gasket to years before replacement is required.The lid of the pressure canner should never be used like the lid on a normal pot. Such will overheat the gasket and dry it out, and will necessitate early replacement. Th chosen, 15 PSI and 15 minutes, is justified as being an overkill method and the product is not considered, since it is of the same overall homogeneous texture in every case due to being blended into a slurry. I have processed over 2000 liter jars of virtually most food produce and ingested all with no spoilage or ill effects. Use the method at you discretion. |

|

|

|

|

|

#161 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

http://www.durgan.org/2015/August%20...HTML/index.htm 27 August 2015 Apple Juice

Twenty pounds of apples were purchased for 12 dollars and made into 14 liters of juice. The apples were washed, quartered,water added about ten liters, cooked until soft, blended into a slurry, strained, placed in liter jars, and pressure canned in two batches of seven at 15 PSI for 15 minutes.The whole apple as used with nothing but water added to make drinkable.

|

|

|

|

|

|

#162 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

Apples are always sweet to my surprise. The juicing method utilizes the whole apple with minimum labor involved. A simple straining is all that is required.I add the juice in the drinking glass to other juices to sweeten to make more appetizing in some cases. My view is a glass periodically is healthy. The apple season is just starting and apples are readily available at low cost.

|

|

|

|

|

|

#163 |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

This completes my garden vegetable preservation for 2015. Now I have the fruit to can as it becomes available.

http://www.durgan.org/2015/August%20...%20Juice/HTML/ 29 August 2015 Six Vegetable Juice It is getting to the end of the vegetable garden season, so the vegetables left were picked and converted into juice. Vegetable available were onions, tomatoes, beets, carrots, green peppers, and Brussels sprouts. The vegetables were washed, cut into smaller pieces, placed in cooking pot with ten liters of water added per batch.The material was cooked until soft about 20 minutes then blended into a slurry.The slurry was screened in a Victorio strainer. The residue was put through a Champion Juicer to extract maximum nutrients. The juice was placed into liter jars and pressure canned at 15 PSI for 15 minutes.A total of 40 liters were obtained. Pictures depict the process.

|

|

|

|

|

|

#164 |

|

Tomatovillian™

Join Date: Jul 2008

Location: 6a - NE Tennessee

Posts: 4,538

|

I just went thru this thread re-reading. As I was doing so, an idea began forming and I thought I'd put it here to get Durgan's comments and possibly other folks experience/judgement.

Durgan is proof that almost anything can be juiced and preserved. Most of our kids today need to get the nutrition from more kinds of veggies. I think we can all agree that most kids need more of the good stuff. So, here's my idea and please comment on it. What if we took some of these great flavor combinations and added them to things that kids eat - like rice and mashed potatoes. With some minor flavor tweaks according to the taste preferences in each household, we might get more brocolli and greens in those growing bodies. Durgan has so many recipes that surely each family can find at least one or two to start with. With some kind of "mask" on what the kids are eating, they might buy in. What do you folks think??? Anybody already try this approach??

__________________

Ted ________________________ Owner & Sole Operator Of The Muddy Bucket Farm and Tomato Ranch |

|

|

|

|

|

#165 | |

|

Tomatovillian™

Join Date: Feb 2013

Location: Brantford, ON, Canada

Posts: 1,341

|

Quote:

Some of the most undesirable namely the typical garden vegetables are easily disguised using simply a small amount of fruit juice added to the drinking glass. This is my method. Most of the mixtures are almost soup and can be incorporated with most soup broths. Anything to get it into little Johnny and Mary. The beauty of the juicing method is almost anything can be readily utilized and stored for off season use. Texture is decided by the amount of water added to the cooking pot. I use no condiments, sugar or salt, but they could be easily added as desired. Never could I eat so much plant food by any other method. I might add these juices could be prepared in small quantities for current use by storing in the refrigerator. This effectively eliminates the canning step. Last edited by Durgan; September 6, 2015 at 04:52 PM. |

|

|

|

|

|

|

|