|

|

#2071 |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

I called the vet and they gave me another number to call and the guy came and picked her up.

Worth |

|

|

|

|

|

#2072 |

|

Tomatovillian™

Join Date: Jun 2012

Location: Illinois, zone 6

Posts: 8,407

|

Random pic: Grandma now has a safety rail by her bathtub so she won't fall any more. It took me forever to find the studs in that wall. The rail came with 3" lag screws and said "must be mounted to wood." LOL, as if anyone has walls that are 3" of solid wood. I bought 2" lag screws instead. The back part is so big, because that is where the wall studs are, on either end of the backing boards.

The rail pivots up against the wall when not in use. $118, Moen brand, ordered from lowes.com The rail claims a 300 lb capacity. I weigh almost 200. I can sit on it and bounce up and down. |

|

|

|

|

|

#2073 |

|

Tomatovillian™

Join Date: Apr 2016

Location: Dallas, TX

Posts: 3,825

|

Funny you should mention it. I am looking for a grab handle. Didn't think the box stores would stock them. Nice looking installation.

__________________

Stupidity got us into this mess. Why can't it get us out? - Will Rogers |

|

|

|

|

|

#2074 |

|

Tomatovillian™

Join Date: Jun 2012

Location: Illinois, zone 6

Posts: 8,407

|

Lowes, Menards and Home Depot have a lot of grab handles. The key is in the mounting, though. If you mount it vertically, as long as you find a wall stud you should be ok.

I was trying to be minimally invasive in putting up the rail. If I had the opportunity to make a big mess, I would have recessed that wood backing into the wall and paneled over it But Grandpa has dementia and he gets really upset when anything is out of the ordinary, so I try to be in and out as quickly as possible. |

|

|

|

|

|

#2075 |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

The lathe does NOT like to go slow here it is spinning a chunk of 4 1/2 inch diameter at 600 rpm which would be 706.858 feet per minute at about 0.005 feed per revolution.

I have tried slow both ways it doesn't give a good finish.  This is straight from the tool no sanding. Worth 20160827_144250.jpg |

|

|

|

|

|

#2076 |

|

Tomatovillian™

Join Date: Apr 2016

Location: Dallas, TX

Posts: 3,825

|

What tool? What material?

__________________

Stupidity got us into this mess. Why can't it get us out? - Will Rogers |

|

|

|

|

|

#2077 |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

Carbide turning and shaping tool and sch 80 pipe.

The inside you cant see was done with a hand ground high speed steel bit on a 3/4 boring bar. It is the beginnings of another contraption I am making. Worth 20160827_182237.jpg |

|

|

|

|

|

#2078 |

|

Tomatovillian™

Join Date: Apr 2016

Location: Dallas, TX

Posts: 3,825

|

That's a pretty slick result. I think you got the feed rate right.

__________________

Stupidity got us into this mess. Why can't it get us out? - Will Rogers |

|

|

|

|

|

#2079 |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

Yesterday I got the bejeebers scared out of me again guess why, my old buddy came by to see me.

He slipped right up behind me.  Worth 20160831_171916.jpg |

|

|

|

|

|

#2080 |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

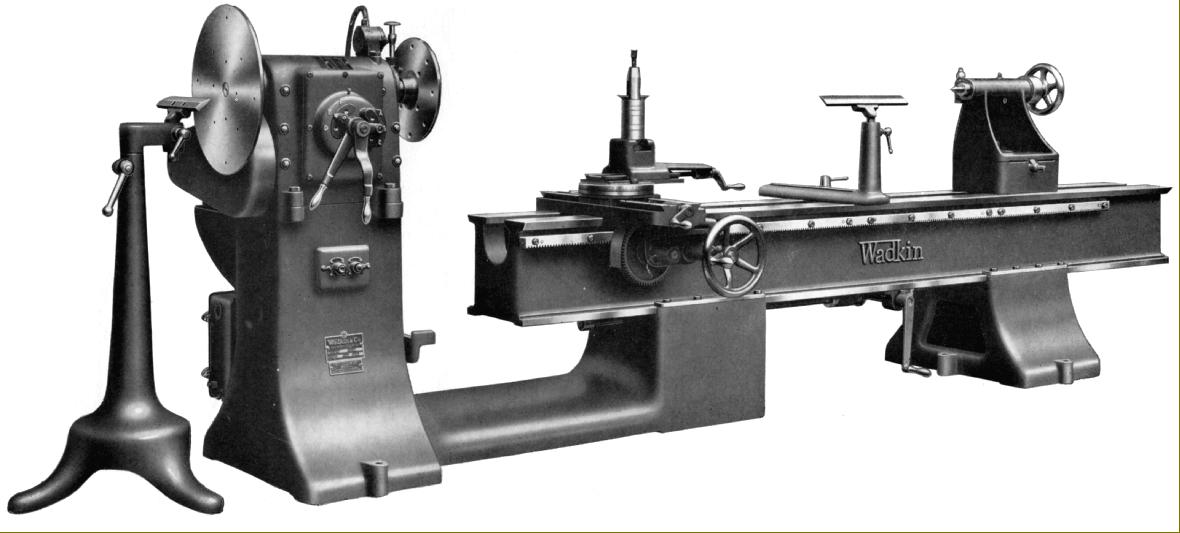

Found this old Wadkin Lathe while looking for ideas.

What a beautiful piece of equipment. In the link is information on them and more models. https://www.google.com/url?sa=i&rct=...105365&cad=rjt

|

|

|

|

|

|

#2081 |

|

BANNED FOR LIFE

Join Date: May 2014

Posts: 13,333

|

I think I saw one of these in a wood shop that was used to make custom cabinets, furniture, and things like grandfather clocks. This was back in the mid 70s. I was only 9 or maybe 10 at the most. The base of the lathe was painted red. I'm not sure if it came painted that color or if it had been restored? The whole shop was amazing. I wish I could have spent more time looking at the tools, but we were there to bid on some masonry work.

That was the first time I saw a hand crank grinder too. Later that year, I saw another grinder like that. It was my stepmother's grandfather's. He raised chickens for Bo Pilgrim. |

|

|

|

|

|

#2082 |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

Salt after doing a lot of reading up a huge percentage of the equipment has the same story be it in the US or in another country.

Out of business in the 70's. Just at the time I was getting out of high school and my whole life ahead of me America was literally falling apart at the seams. I have a childish dream that one day that manufacturing will come back to America. The old wood lathe in the pictuer was made in the UK they suffer as we do. Worth |

|

|

|

|

|

#2083 |

|

BANNED FOR LIFE

Join Date: May 2014

Posts: 13,333

|

That is a good dream to have Worth - a very good dream.

|

|

|

|

|

|

#2084 |

|

Tomatovillian™

Join Date: Feb 2006

Location: Den of Drunken Fools

Posts: 38,539

|

The problem is good stuff lasted a long time.

Without a growing industry there was no need for more equipment like this or at least not enough to keep the manufacture in business in the US. Some if not most moved over seas. Now a lot of that old stuff is wearing out and way too big for the home owner to use so it ends up in the scrap yards.  Worth |

|

|

|

|

|

#2085 |

|

Tomatovillian™

Join Date: Jun 2013

Location: Wasilla Alaska

Posts: 2,010

|

Spent a week in the mountains, a few extra were not by choice either, the rains found us in time. A pic of Denali about 80 miles away.

|

|

|

|

|

|

|